Aquatron Laboratory: Marine Laboratory Retrofit

Nova Scotia, Canada

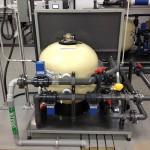

After an efficiency audit, Aqua Logic was subcontracted by Johnson Controls to provide the Dalhousie University’s Aquatron Lab with 18 turnkey filtration systems on skids to replace existing systems in several labs within the aging facility. Ten were used as small recirculating aquaculture systems (RAS), four were used on larger RAS, and the remaining four as auxillary RAS to boost the smaller skids when needed. Aquatron rents lab space for marine research and wanted these systems to be versatile enough to establish and maintain any desired parameters.

Components & Features

- Built a total of eighteen (18) skids

- 10 small skids had a 4’ x 4’ footprint requirement and each skid included: (2) VFD pumps, (2) 18” sand filters, a 6kW heater, 1.5hp water cooled-chiller marine duty chiller, (2) 50 watt UV sterilizers.

- 4 large RAS had an approximate 4’ x 8’ footprint and included: (2) VFD pumps, (2) 36” sand filters, (1) 6kW inline heater, a 1.5 HP water-cooled marine duty chiller, and (2) 80 watt UV sterilizers.

- The auxiliary RAS had a 4’x4’ footprint and included: a VFD pump and a 36” filter.

- Automated backwash was provided for all the filters and was controlled based on differential pressure in and out of the filter.

- PLC panel was provided for each skid and networked back to the main LSS computer system. For monitoring and alarm capability only.

- Each panel had a color touch screen for equipment controls at a local level.

- Pressure sensors, temperature sensors, pH sensors, and UV light transmittance sensors.

- The small and large RAS each had their own sump with stilling well and ultrasonic level sensor, as well as a degassing tower filled with bio-balls.

- Each skid was CSA certified prior to shipping to Canada.